PETROLUXE GROUP

Leveraging the robust resources of our parent company, YIHONG NEW ENERGY CO LTD, in the refining sector, we primarily rely on Tianjin Jiangdong Petrochemical Co., Ltd. and Dongying Ruiying Petrochemical Co., Ltd. in China. These two companies are primarily engaged in petrochemical processing, storage, and trading, possessing extensive experience in the petrochemical field.

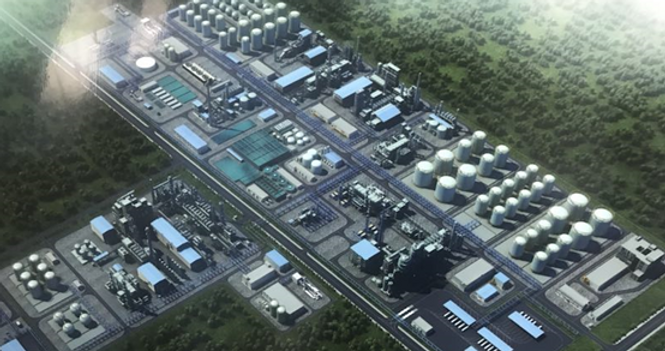

The company's petroleum storage business is an important auxiliary service to its refining operations. The construction project will reference successful cases from YIHONG headquarters, relying on the parent company's construction drawings and professional engineers. In Malaysia, we will construct an oil storage tank area with an estimated capacity of 300,000 tons.

The company is equipped with research talents and engineers in various fields for research and operations. Regarding product development, based on the company's strategic planning and research directions concerning market demands, environmental concerns, energy considerations, and product upgrades, the company's specialized research team focuses primarily on environmental protection and safety research. This focus aims to provide customers with higher quality products and greater added value.

In terms of production and transportation operations, the company rigorously selects and evaluates engineers at every level to ensure product quality, operational safety, and environmental protection. This approach aims to enhance customer experience, protect social interests, and safeguard the global environment.

Technically, the project adheres to principles of technological advancement, reasonable investment, energy efficiency, and good economic returns. It adopts optimized processing schemes and processes, advanced energy-saving technologies, and energy-saving equipment measures in the design of atmospheric distillation unit projects. These measures aim to achieve high yield and low energy consumption while meeting production and product quality requirements.

The project meets the overall requirements for processing low to medium sulfur, condensate and fuel oil with a density between 0.7-0.88 g/cm³, and sulfur content not exceeding 10,000 ppm. The technological level has reached an advanced domestic standard.

Given that naphtha and crude liquid wax represent future market demand trends, our company has formulated decision recommendations after conducting extensive market research. In order to further enhance, improve, and expand the naphtha and crude liquid wax markets, our company has strategically planned the rational configuration of product structure to obtain high-quality and high-value-added products.

Currently, both the international and domestic refining industries are moving towards large-scale development to reduce unit processing costs and enhance competitiveness. In recent years, regional refining enterprises have experienced rapid growth, with increasing processing scales. Therefore, our company has taken an innovative approach by introducing a new condensate processing project to increase processing depth and product added value, further meeting customer demands.

The raw material for this project is based on medium to low sulfur condensate oil sourced from Malaysia and surrounding areas, with a density ranging from 0.7 to 0.9 g/cm³ and sulfur content less than 1.0 w%. The processing of condensate oil in this project involves three stages: flash distillation, atmospheric cutting, and atmospheric refining. After desalting treatment, the raw condensate oil is sequentially processed through flash distillation towers and atmospheric cutting towers, utilizing the different relative volatilities of components in the condensate oil to fractionate products such as light hydrocarbons, light naphtha (ethylene feedstock), 1# naphtha (reforming feedstock), 2# naphtha (solvent naphtha), light diesel, and crude liquid wax.

We plan to invest $2,000,000 in three phases to build a world-class oil storage and refining plant in Malaysia. We aim to create over 2500 job opportunities locally and provide training for employees. The first phase of the project involves the construction of storage and refining facilities. The second phase entails a massive 800,000-ton PX aromatic hydrocarbon unit, prepared in two stages. The third phase continues the advancement of the PX aromatic hydrocarbon comprehensive facility project.

The products of the first phase mainly include fractionated oil, liquefied petroleum gas, light initial naphtha, heavy naphtha, and light diesel.

Main Products and Production Capacities:

- Light hydrocarbons: 30,000 tons/year

- Light naphtha (ethylene feedstock): 200,000 tons/year

- 1# naphtha (reforming feedstock): 250,000 tons/year

- 2# naphtha (solvent naphtha): 220,000 tons/year

- SA-1000 high-boiling point aromatic solvent oil: 140,000 tons/year

- SA-1500 high-boiling point aromatic solvent oil: 80,000 tons/year

- Diesel: 200,000 tons/year

- Crude liquid wax (paraffin oil/fuel oil): 120,000 tons/year

- Gasoline: 300,000 tons/year

Gasoline products are based on light hydrocarbons and naphtha as base oils, blended with some externally sourced high-octane components, and sold externally after meeting standards.

Safety is the cornerstone of PETROLUXE refinery's excellent operation. All operational departments continuously review and upgrade health, safety, and environmental practices. The refinery operates in accordance with the Control of Major Accident Hazards (COMAH) regulations and collaborates closely with the Health and Safety Executive (HSE) and the Environment Agency (EA) in the UK.

As energy supply becomes increasingly tight and energy prices continue to rise, it is increasingly important to improve the comprehensive utilization level of device energy, reduce energy consumption and thereby reduce production costs to improve the economic benefits of production units. Therefore, this project adopts current domestic advanced energy-saving measures to reduce the energy consumption of the device.

The project energy consumption index is a comprehensive index calculation based on the total net increase in physical energy consumption. The calculation method adopts the provisions of "Petrochemical Engineering Design Energy Consumption Calculation Standard" GB/T50441-2007.

The processing energy consumption of the condensate processing project is 18.09Kg/t of raw material. Since the device adopts advanced process routes, the overall energy consumption is at a better level than similar domestic devices.